Search This Supplers Products:plastic injection mouldplastic injection serviceCNC prototype

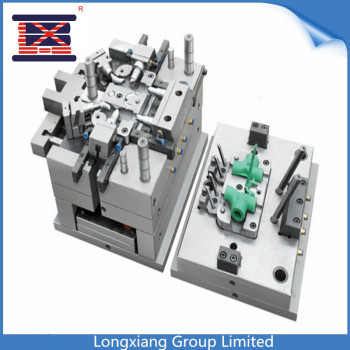

Custom Made Plastic Medical Parts Mold And Polypropylene Injection Custom Injection Molding factory

- group name

- Plastic Injection Mold

- Min Order

- 1 set

- brand name

- LONGXIANG

- model

- LX-062

- Nearest port for product export

- Guangzhou, Shenzhen, Hongkong

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CIP

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union, Cash

- update time

- Wed, 28 Mar 2018 11:28:08 GMT

Paramtents

Mold Material 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343,

Product Material ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc

Mold Standard HASCO, DME, MISUMI, JIS, LKM, etc.

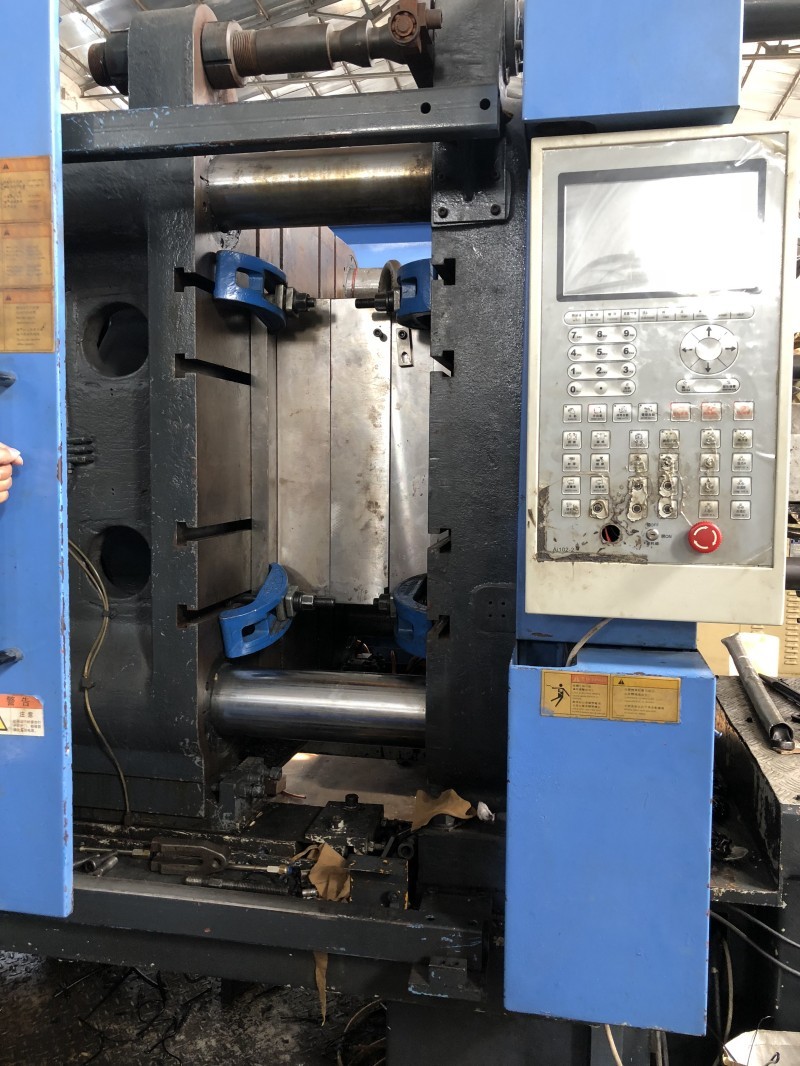

Injection Mold Machine 80T to 2800T

Mold Tooling Equipment Lathe,Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine

GateType Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc.

Runner Type Cold Runner or Hot Runner

Cavity Single or Multi cavities

Mold Life 5000-500,000 shots

Lead Time About 30 days

Packging & Delivery

- 100cm x100cm x100cm

-

Min Order1 set

Briefing

Detailed

| Mold Material | 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

| Mold Type | Plastic Injection Molding |

| Product Material | ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc |

| Mold Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold Tooling Equipment | Lathe,Milling,Grinder,Drill,CNC,EDM, Wire cut machine,Punch machine |

| Injection Mold Machine | 80T to 2800T |

| Product Weight | 50-20000g |

| GateType | Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

| Runner Type | Cold Runner or Hot Runner |

| Cavity | Single or Multi cavities |

| Treatment | Heat treatment and Nitriding,polish ect. |

| Mold Life | 45#:50,000 to 100,000 shots |

| P20:100,000 to 200,000 shots | |

| 718: 200,000 to 300,000 shots | |

| H13: 300,000 to 500,000 shots | |

| Lead Time | Generally mold making will take around 30 days 7-10 day to mass production |

| Package | Wooden packing box for molds inner packed in opp bags, outside packed in standard export carton |

1. Q: Which kind of product can you do?

A: Plastic injection molding and mass production for plastic parts.

2. Q: Which kind information need for quotation?

A: 1) Sample photo with size or 2D/3D design

2) Product material

3) The quantity

4) Runner type, cold or hot

5) Mould steel type, P20, 718, 2738, H13, S136, 2316, an so on.

3. Q: I have no 3D drawing, how should I start the new project?

A: You can supply us a sample or tell me your idea,we will help to finish the 3D drawing design.

4. Q: How long will be the injection mold finished?

A: Usually it will take about one month to finish the mold.

5. Q: How about the samples?

A: After mold finished, We will make some samples for you to check as soon as we finish the mold and then deliver the samples for you to check.

6. Q: How about the mould modify?

A: You can tell us your comment about the samples after you receive them.If there is any dimension different from the drawing,we will modify the mold for free in our side and then make the new samples.

7. Q: How about the proprietary rights of the plastic injection mold?

A: Customer paid the mould so it all belong to Customer.

| Plastic Mold (Moulds) production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2 .Negotiations | Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, part cost, payment, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold(moulds) | Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer a mold progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15 piece), then, get your signature sample ,mass production. |

| 7. Package | Wooden case for moulds, cartons for parts ,or as your requiretment. |

| 8. Delivery | deliver goods by air or by sea. |